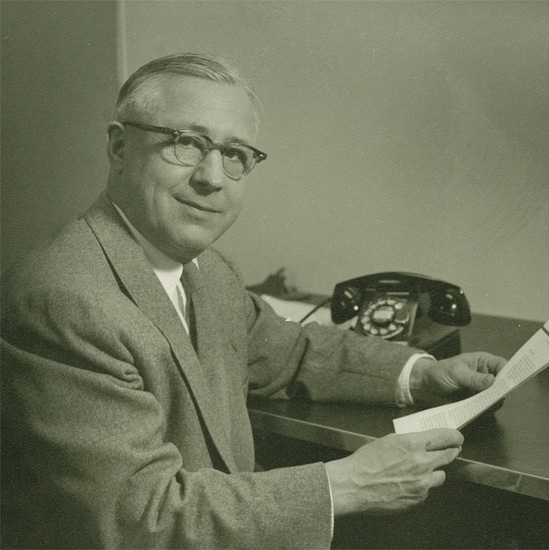

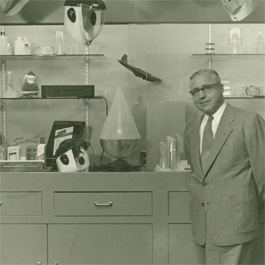

Louis Pfohl founded Plaxall in the heart of Long Island City over 75 years ago, with the help of his wife Pauline Mathis Pfohl. A pioneer in the plastics industry, Mr. Pfohl was the originator of the process known as Thermoforming. He immediately recognized Long Island City’s potential not just as a manufacturing hub, but also as a bustling neighborhood for families that offered opportunities for diverse business growth.

With the success of the plastics business, Louis and Pauline were able to invest in local property. Their son James Pfohl ran the company for many years and, with the help of his sisters Ann Pfohl Kirby and Lynn Pfohl Quigley and later his nephew Andrew Louis Kirby, continued to expand the property holdings. Today the Plaxall team of third generation family members – Paula Kirby, Tony Pfohl and Matthew Quigley – manage over one million square feet of space, in addition to running the manufacturing business.

Plaxall has worked to cultivate a community within its properties, from providing space for local non-profit organizations like LIC Community Boathouse and Recycle-a-Bicycle to co-founding and sponsoring the popular LIC Flea & Food. Plaxall also proudly supports local businesses and civic organizations such as the Coalition for Queens, the Jacob A. Riis Settlement House, LIC Cultural Alliance and the LIC Partnership, among many others, through the Mathis Pfohl Foundation and – in several cases – active Board membership.

We’ve been a proud supporter of numerous outstanding community organizations for generations. These groups have helped make both LIC and New York a better place to Live, Work, and Visit.